This means you should always have at least 50 phone cases in stock to avoid running out before your next shipment arrives. Its calculation is not a difficult task, but you will first need to make another formula, referring to the average daily consumption of a certain commodity. Minimum stock is a well-known expression for storekeepers and managers in general. Despite this, it is not uncommon to find professionals who have doubts about what this expression is and how to calculate this index.

Warehouse solutions

Our inventory solution even allows you to set automated order rules and generate purchase orders with one click. Seasonal demand is common across many industries, and maximizing sales during peak periods relies heavily on accurate inventory forecasting. It isn’t difficult to see why businesses continually strive to optimize stocks, given the many advantages. Businesses can face sweat when stock runs low, leading to frantic reordering and potential stockouts.

Fasten purchase orders to ensure steady inventory levels 🛒

While it’s important to have sufficient inventory to meet market demand, excess inventory can leave a company with low cash flow and many unsold products. This has revealed the limitations of the classic minimum/maximum stock rule. Trying to adjust it to an increasingly complex reality lies in integrating specialized logistics management software and basing decisions on measurable data. This method is more complex, involving several parameters in the calculations. I recommend using it when your stock management presents many uncertainties and high stock levels.

Minimum stock vs. Maximum stock

Discount, bundle, or donate items that have become obsolete to prevent them from occupying valuable warehouse space and accruing holding costs. In most cases, safety stocks are necessary for companies operating with slow slow-moving. Our non-GAAP financial measures reflect adjustments based on the following items. About iRobot Corp.iRobot is a global consumer robot company that designs and builds thoughtful robots and intelligent home innovations that make life better.

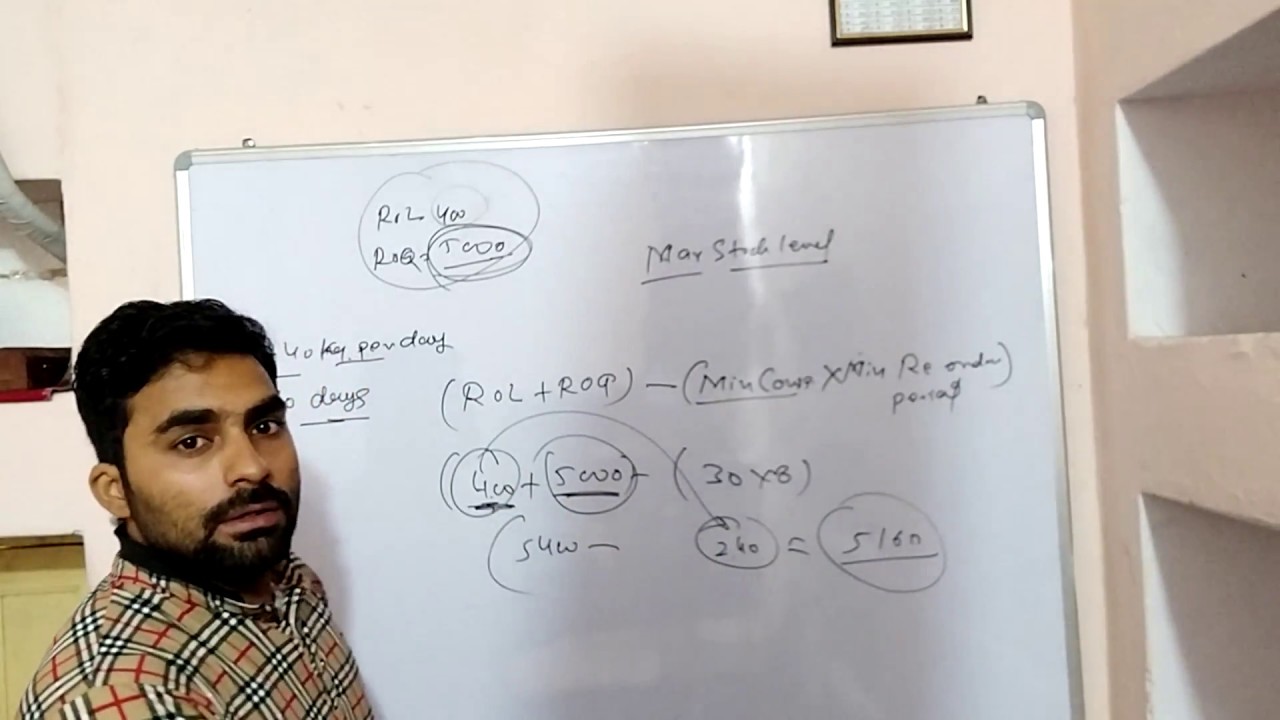

And that means they’re more likely to come back and purchase from you again and again. It can be calculated by adding the maximum and minimum stock levels and dividing by two. Now that we’ve discussed why it’s important to know your minimum inventory levels let’s talk about how to actually calculate them. The maximum demand is 20,000 shirts per year and the average demand is 18,570 shirts per year. Now that we’re clear on these concepts, we can calculate the optimal stock level. The reorder level is the inventory level at which a new order should be placed to replenish stock.

Get in touch and we’ll provide you with a personalised demo of Easy WMS with all the control and stock management functionalities you need. Explore how to calculate ending inventory accurately for better stock and profit control. Established companies can rely on historical sales data to calculate the above. Start-ups and newly founded companies, on the other hand, must first estimate their daily sales and adjust the values regularly. (1) Non-GAAP Days in inventory is calculated as inventory divided by (Revenue minus Non-GAAP Gross Profit), multiplied by 91 days.

- It isn’t difficult to see why businesses continually strive to optimize stocks, given the many advantages.

- But if you proactively get rid of these dead stock items, you can get ahead of the problem and get closer to optimal levels.

- Additionally, factors like supplier delays or disruptions in the supply chain can affect the availability of products and influence inventory levels.

- Having a WMS makes it possible for the installation to process unplanned receipts and organize the subsequent location management of these goods.

If you’re overwhelmed by the idea of tracking all these metrics manually, it’s high time to invest in an inventory management solution like SkuVault. Artificial Intelligence (AI) uses advanced analytics and learning algorithms to automate and improve inventory processes. AI can analyze vast volumes of data, translating historical and external demand variables into actionable forecasts. Machine learning ensures that forecasts become increasingly more responsive and accurate. Businesses that monitor inventory in real time and use advanced analytics can respond quickly to these challenges. Those that do, have a competitive advantage over businesses without the same capabilities.

If inventory falls below the minimum level, it could lead to stockouts, unhappy customers, and a loss in profit. Moreover, these applications calculate the optimal stock levels for each SKU, which will automatically generate replenishment tasks for products below the preset limit. Inventory management software is designed to help you efficiently track, organize, and control your inventory levels. This software provides real-time visibility into stock levels, automates inventory processes, and streamlines tasks like inventory tracking, order management, and replenishment.

This leads to lost revenue and frustrated clients, some of whom may shift to a competitor. Imagine you sell bathing suits—usually considered seasonal inventory rate of return ror meaning formula and examples since people tend to buy them during warmer months. For this reason, retailers in your industry might let inventory levels drop slightly during colder seasons.

Despite strategies such as the just-in-time system, which aims to approach the zero-stock paradigm, storing goods is and will always be necessary for the proper functioning of the supply chain. It provides a higher level of customer service by ensuring that stocks are replenished before they fall below the minimum levels. It also reduces risk exposure to stoppages in production and sourcing problems. Learn the difference between demand planning and supply planning in ecommerce.

You must also consider the reorder point, which is the point at which you must reorder inventory from suppliers. External factors such as market trends or seasonal demand fluctuations can significantly impact the accuracy of minimum inventory level calculations. For example, sudden changes in consumer preferences or unexpected spikes in demand during certain periods can lead to deviations from predicted demand patterns. Additionally, factors like supplier delays or disruptions in the supply chain can affect the availability of products and influence inventory levels. Businesses need to regularly monitor and adjust their minimum inventory levels based on real-time data and insights to effectively navigate these external dynamics.